MANUFACTURING INSTRUCTIONS ACCORDING TO EN ISO 20345/20347 (DGUV 112-191)

The manufacturing instructions for EN ISO 20345/20347 (DGUV 112-191) are available for download below the text.

Simply click on an icon and you will receive a PDF file that you can save and/or print. Alternatively, you can select several files using “Add” and receive a .zip file with the selected manufacturing instructions via “Download”.

If you have any questions, please contact our team at service@elten.com.

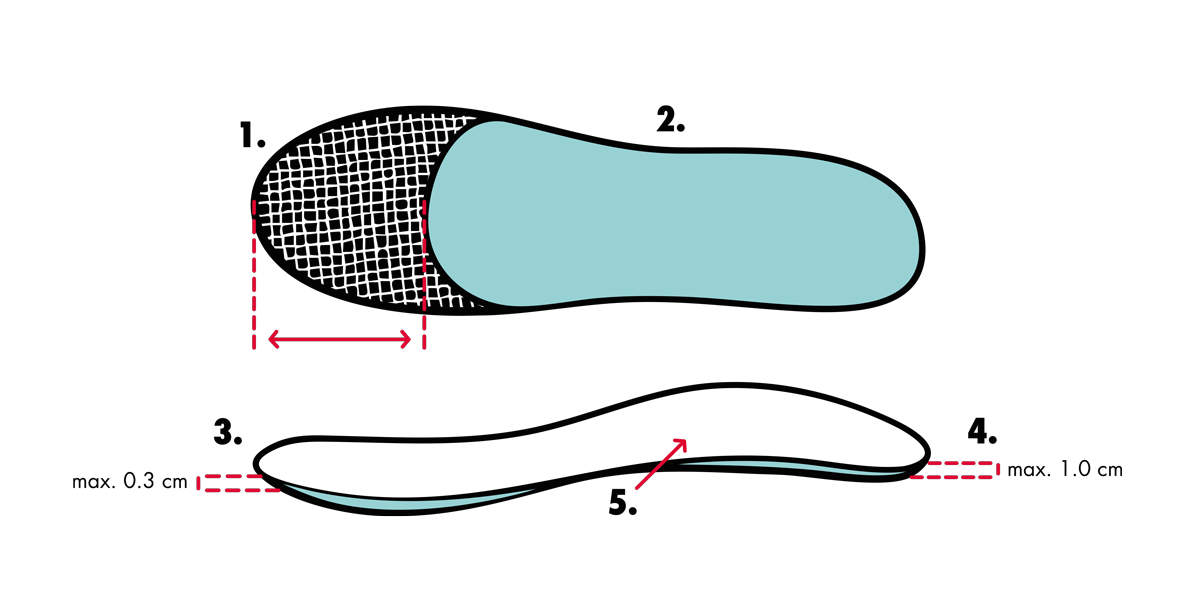

INSOLE

- Non-modifiable area: Only the ESD PRO insole material may be used below the toe cap.

- Customisable area: This area can be customised, taking into account the permissible material thicknesses.

- Material thickness in the non-modifiable area: The maximum material thickness is 0.3 cm.

- Material thickness in the customisable area: The maximum total material thickness is 1.0 cm.

- Suitable upper material of the insole: Either the ESD PRO insole or the ESD sheet material can be used as the upper material of the insole.

Here are the details again, as applicable to all certified models:

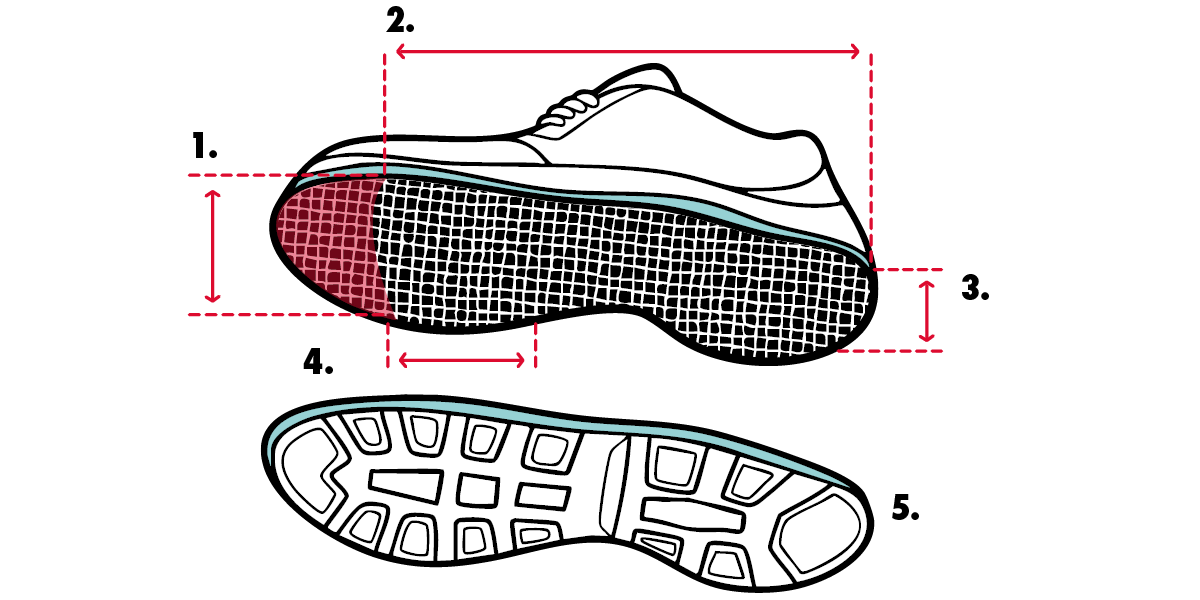

OUTSOLE

- Build-up material in the toe cap area: Only the Star HD heel plate may be used below the toe cap.

- Build-up material behind the toe cap area: Stapur in black or white is permitted.

- Build-up height in the heel area: Maximum 3.0 cm.

- Build-up height in the ball area: Maximum 1.5 cm.

- Bonding of the outsole: The original outsole must be bonded with Ultraflex 4822N antistatic adhesive.

Here are the details again, as applicable to all certified models:

Manufacturing Instructions